Description

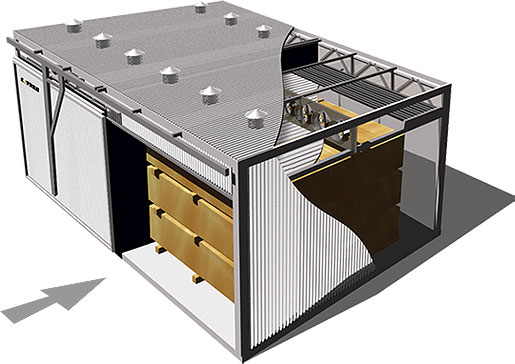

The equipment allows to dry the material with low management costs and efficiently. With the conventional KATRES KAD type dryer, it is possible to achieve the best quality of dried wood at the lowest possible price and early return on investment. As standard, the material is loaded on one side with a front loader, but KATRES can also offer a modified version with double-sided loading. As a main product, KATRES produces dryers in the size of 29 – 240 m3, for all markets. The design of KATRES dryers is based on individual customer requirements. All load-bearing parts, beams, sunroof and construction are made of first-class aluminum profile, stainless steel. The dryer wall system meets the strictest thermal insulation criteria. The air circulation in the dryer is ensured by efficient rotating fans with a diameter of up to 1600 mm (depending on the type of dryer), which together with the intelligent ECO-TRONIC speed flow control results in significant energy savings. Low heat consumption is achieved through an efficient heat recovery unit. The quality of the final product is guaranteed by a low or high pressure irrigation system. The entire wood drying process is fully controlled by the MK-520G automatic control system. You can choose between pre-set drying programs or set more suitable drying schedules and additional parameters.